Everything You Need to Know About Shipping Containers

Shipping containers are the backbone of global trade, enabling efficient transportation of goods across vast distances. They account for 95% of all cargotransported by ocean and play a crucial role in international commerce.

But what makes them so essential? Let’s break down their history, types, uses, and how they revolutionized global shipping.

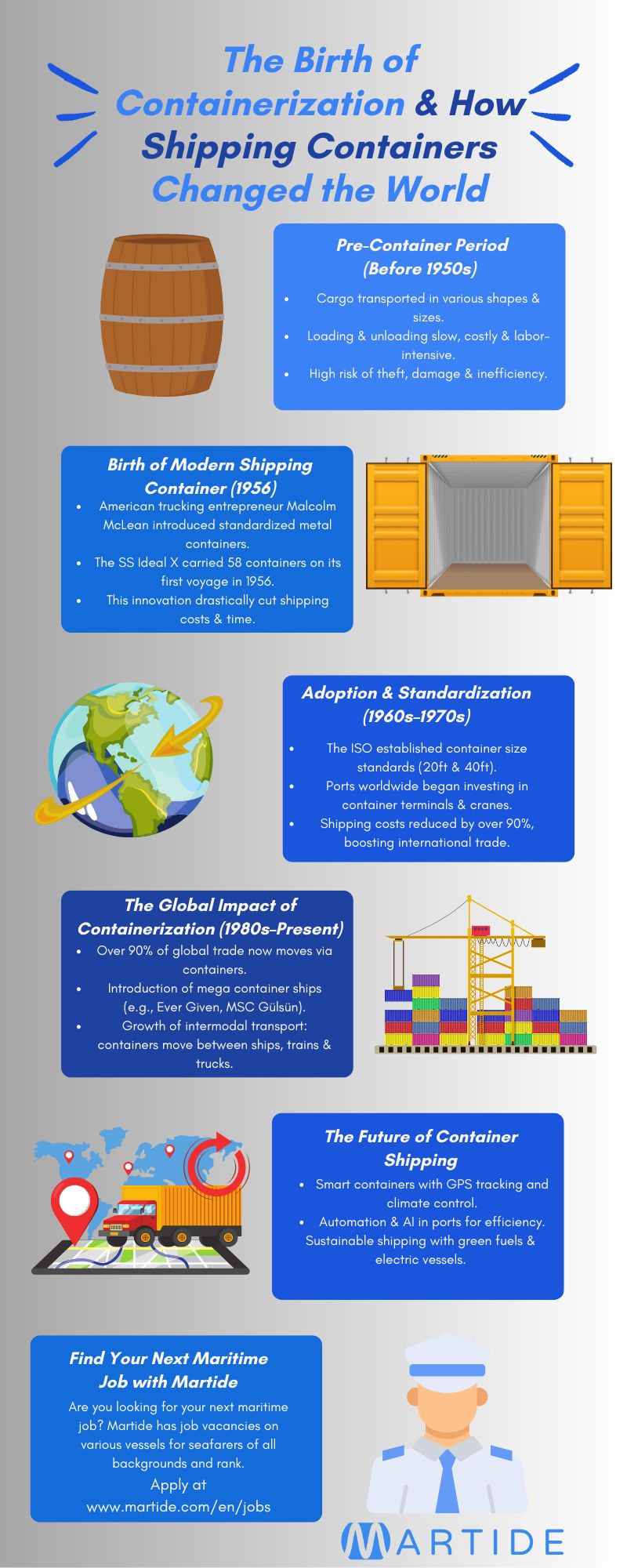

The History of Shipping Containers

The modern shipping container was pioneered by Malcolm McLean in 1956. As a trucking company owner, he sought a more efficient way to transport goods between trucks and ships without unloading cargo. His innovation reduced loading costs from $5.86 per ton to just $0.16 per ton (in 1956 prices), drastically improving efficiency.

Key Milestones:

- 1956: McLean introduced the first standardized steel shipping container.

- April 26, 1956: The "Ideal X" became the first freighter to carry McLean’s containers from Newark to Houston.

- 1957: The "Maxton" was the first ship specifically built for container transport.

- 1960s: The ISO (International Organization for Standardization) established global size standards: 10, 20, 30, and 40 feet in length, with a width of 8 feet and a height of 8 feet 6 inches.

These advancements laid the foundation for the modern intermodal transportation system, allowing seamless movement of containers via ship, rail, and truck without repacking.

Types of Shipping Containers

Different shipments require different containers. Here’s a breakdown of the most common types:

| Container Type | Description | Best Used For |

| Dry Storage | The most common container, available in 10ft, 20ft, and 40ft sizes. | General dry goods |

| Flat Rack | Collapsible sides for oversized cargo. | Vehicles, machinery, boats |

| Open-Top | Roofless container for taller cargo. | Logs, construction materials |

| Refrigerated (Reefer) | Temperature-controlled container | Perishable goods (food, medicine) |

| Open-Side | Side doors allow wider loading | Large or irregularly shaped items |

Container Shipment Methods

When shipping goods, two primary methods determine how cargo is packed:

1. Full Container Load (FCL)

- Used when one recipient receives all goods.

- Maximizes container space, reducing per-unit costs.

- Best for businesses with large shipments.

2. Less than Container Load (LCL)

- Multiple shipments share one container.

- Ideal for smaller businesses that don’t require a full container.

- Cargo is consolidated at a Container Freight Station (CFS) before being shipped.

Shipping, Storage, and Conex: What's the Difference?

| Term | Definition |

| Shipping Container | Used for transporting goods internationally. |

| Storage Container | Repurposed for long-term storage on land. |

| Conex Box | A military term from the 1950s for a standardized modular container. |

Many containers start as shipping containers before being converted into storage units or other applications like modular homes and pop-up shops.

Read more: What Are Shipping Alliances in the Maritime Industry?

The Impact of Shipping Containers on Global Trade

- Efficiency: Reduced loading/unloading times and costs.

- Security: Goods remain sealed throughout transit.

- Scalability: Standard sizes allow for easy stacking and transportation.

- Sustainability: Containers can be repurposed for alternative uses, reducing waste.

Without containerization, modern global trade as we know it wouldn’t exist. Today, millions of shipping containers move across the world daily, keeping supply chains running smoothly.

Final Thoughts

Thanks to Malcolm McLean, containerization has become the most efficient, cost-effective, and secure method of transporting goods worldwide. The industry not only supports global trade but also provides millions of jobs in the logistics and maritime sectors.

Whether you're a shipping professional or just curious about global logistics, understanding shipping containers is key to grasping how our modern economy functions.

Interested in a career in maritime shipping? Martide helps seafarers connect with top employers.

Create a resume, browse our vacancies, and apply via the mobile app today.

This blog post was originally published on February 6th 2023 and rewritten on February 20th 2025.

Gavin Hirst

Gavin is a contributing writer to the Martide blog who covers topics ranging from life at sea to maritime crew management software. A native Brit who is now based in Auckland, NZ, Gavin is also an SEO expert and partner in a successful digital marketing agency that has offices in New Zealand and the United Kingdom.

New Zealand