There are a few facts that are set in stone when it comes to the world's merchant fleet: 1) most vessels are almost always on the move, 2) there are a lot of older ships and tankers still in use and 3) in the event of damage or a fault, procuring a spare part while at sea is borderline impossible.

This means that many repair and maintenance issues can only be dealt with while a vessel is at a port or in a dry dock. So wouldn’t it be great if shipowners could find a way around that and be able to fix problems mid-voyage?

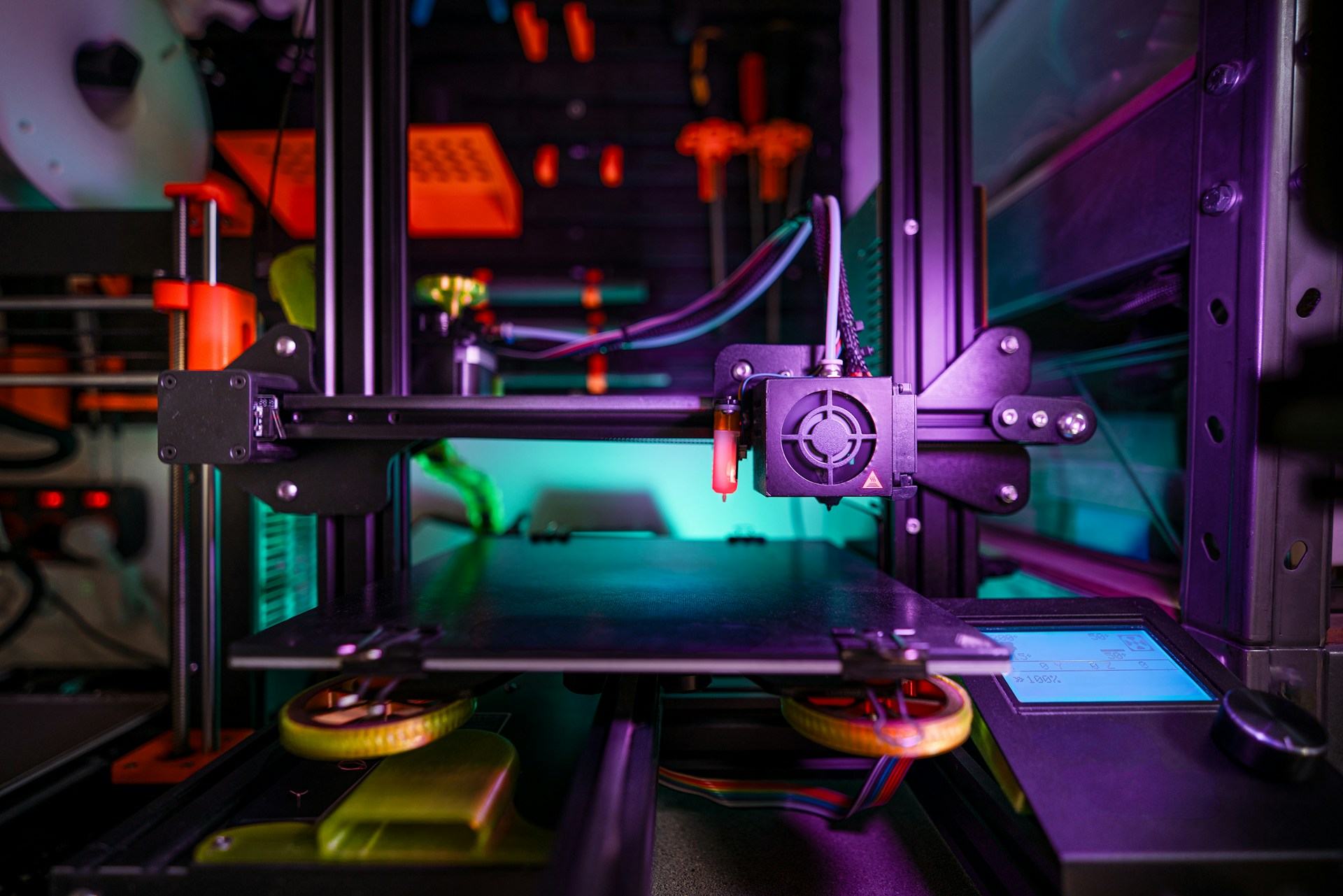

Welcome to the weird and wonderful world of 3D printing.

3D printing has taken a firm foothold in many industries and is being used to create everything from sports shoes to prosthetics for use in the medical industry to art and sculpture.

However, one industry that hasn't been quite so quick to adopt 3D printing is the maritime industry.

In some ways this isn't a shock. After all, the shipping industry has never been particularly known for embracing new technologies with mass enthusiasm. But given the sheer size of vessels and the requirements for highly compatible materials - and not to mention the strict regulations in the sector, it might not be that surprising.

Having said that, companies in the maritime industry are starting to look more closely at the benefits of 3D printing for vessel design and build as well as for repair and maintenance.

Technology is changing shipping. In fact, it always has been, albeit it at a slower pace than comparative industries such as automotive. Paper maps and charts have give way to ECDIS and you'd be hard pushed to find a cargo or container ship that plots its journey by the stars. But what about 3D printing?

What is 3D printing and how does it work?

First of all, what exactly is 3D printing?

3D printing is also known as additive manufacturing. Additive manufacturing is defined as the “process of joining materials to make objects from 3D model data.” At the moment there are seven different additive manufacturing techniques that are referred to as 3D printing.

The best known of these techniques is called material jetting: A process in which layers of plastic wire are melted one on top of each other to create a 3D structure. There is also something called powder-bed extrusion which is of particular interest to the shipping industry as it has the ability to form complex metal structures.

3D printing in the shipping industry: pros

There are a number of benefits to adopting 3D print techniques for companies in the maritime industry. The most obvious of which is being able to repair a vessel while she is at sea as this will, at least temporarily, stem any safety or efficiency issues until a port or dry dock can be reached.

And while it’s unlikely that large parts could be printed during a voyage, there is no reason why basic spares such as impellers or valves couldn’t be printed out and put to use in the event of an emergency.

Once docked, delays can also be kept to a minimum thanks to 3D printers at a port being used as a solution to produce spare parts for ships there and then - as opposed to them having to be transported from a manufacturer inland.

This is clearly beneficial for the shipping company for a number of reasons:

- Transportation costs from a shore-based parts manufacturer to the port and vessel are eliminated

- Wait times - often weeks long - for a specialist part to be manufactured and transported to the port are also exponentially reduced

- Delays of cargo, which result in huge costs and have a massive knock-on effect on the supply chain, are also kept to a minimum - even more so if a vessel can be repaired whilst at sea

Thus there are definitely valid reasons for exploring options such as installing a 3D printer onboard vessels, as well as establishing 3D printing hubs at ports.

3D printing in the shipping industry: cons

Not that long ago, there were still a few cons when it came to using 3D printers in the maritime industry for repairs and maintenance.

For example, 3D printers did not have the skills or capabilities to cut threads or polish parts meaning that certain components would still need to be finished by machine. That, however, has changed, even since we first wrote this article a couple of years ago!

One thing that might still be an issue is the fact that many of a vessel's parts are manufactured from a number of different alloys and that would mean keeping a comparable amount of metals onboard in order to be able to print those spare parts. Not very practical in terms of space and DWT.

This would mean a ship would still need to call at a port for repair by printed parts and those ports that have 3D print facilities would also need storage space for the vast quantities of different metals and alloys. And that storage space would need to have controlled conditions to avoid material corrosion.

On the upside though, as we've seen, the costs and time involved in a vessel's repair would be dramatically less than if traditionally manufactured parts were relied upon.

There are other issues to address before the industry adopts 3D printing as standard practice too: The quality control and regulation of printed components, the protection of intellectual property rights and the training of personnel to name just three.

The automotive and aerospace industries are changing the future of their industries and have embraced 3D printing and additive manufacturing. It remains to be seen whether the shipping industry is quite so welcoming.

How can Martide and technology help you?

If you’re a shipowner, ship manager, crew planner or manning agent with an interest in how technology and software solutions can make life easier, you'll want to know more about our crew planning system and maritime recruitment software as a service.

We may not have the technology of the future in our hands but we think we do a pretty good job of streamlining your maritime recruitment processes!

Want access to a greater pool of seafarers? Looking for a better applicant tracking system? Want an easier way to plan crew and meet changeover dates?

From advertising your jobs to scheduling interviews to booking flights, Martide's recruitment and crewing software has you covered.

Contact us today to find out more or to schedule your free no-strings attached demo.

This article was originally published on September 25th 2019 and updated on October 18th 2022.

Eve Church

Eve is Martide's content writer, publishing regular posts on everything from our maritime recruitment and crew planning software to life at sea. Eve has been writing professionally for more than two decades, crafting everything from SEO-focused blog posts and website landing pages to magazine articles and corporate whitepapers.

UK