A tanker is a ship that transports any type of liquid cargo in bulk. It does not use containers or barrels but stores the liquid in question in a hold. The majority of tankers carry oil - hence the name oil tanker. However some tankers also move edible oils and other liquified foods and beverages such as treacle/molasses and wine.

As you might expect, there’s quite a lot more to the oil tanker than that and we’re going to take a more in depth look at tankers in this article.

This is one of a series of blog posts that explores different vessels, what they are, what they are used for, how they are designed and built, their history and even some odd fun facts here and there!

Read more: Everything You Need to Know About Coaster Vessels

You can find out more about lightships (AKA floating lighthouses!), ferries, icebreaker ships, heavy lift vessels, feeder vessels, dredgers, chemical tankers, car carriers, RoRo ships, bulk carriers, crane vessels, cruise ships, fishing boats and of course, cargo and container ships in our other articles.

But for now, let’s continue to find out more about oil tanker vessels.

What are oil tankers and what do they do?

Like their cousins the container ship, the heavy lift carrier or the gas carrier ship, oil tankers can also vary dramatically in size and length.

ARE YOU LOOKING FOR JOBS ON OIL TANKERS? VIEW MARTIDE’S OIL TANKER JOBS NOW!

Some tankers are on the smaller side, measuring around 200 feet (60 meters) long and carrying 1,500 to 2,000 DWT (deadweight tons).

These tend to be coastal ships which ply their trade around the same island, region or continent, traveling along a coastline and not crossing an ocean.

Read more: Everything You Need to Know About Mining Ships

Meanwhile their bigger sisters can measure up to 1,300 feet (400 meters) in length and can carry a much larger 550,000 DWT, making them the real behemoths of the seas.

Wait! What’s DWT?!

DWT stands for deadweight tons. Deadweight is the total weight of cargo onboard a vessel plus any necessities such as fuel, fresh water, lubricating oil, gear, other supplies and, yes, the crew too.

What do oil tankers actually do?

Like all merchant ships, tankers exist to transport a commodity from one place to another.

In this case, this will normally either be carrying crude oil from oil fields to refineries, or petroleum products including fuel oil, diesel fuel, petrochemicals and gasoline/petrol from refineries to a distribution point nearer to the market of consumption.

Read more: Everything You Need to Know About Tugboats

These tankers are broken down into two basic types: crude tankers (transporting crude oil) and product tankers (transporting petroleum products.) Of the two, the product tanker is usually a lot smaller in size.

And talking of size…

Oil tanker classification according to size

Like bulk carriers which are divided into types such as Handymax, Supramax and Panamax, because of the huge difference in length and DWT, tankers are broken down further into size classes.

Read more: Everything You Need to Know About Cable Laying Ships

Bear in mind that the specifications, and even some names, for these classifications can vary depending on where you’re reading about them and according to various different organizations and countries. But generally, these breakdowns are:

General Purpose / Small Range tankers

- Are normally up to 650 feet (200 meters) long

- Have a capacity of between 10,000 to 60,000 DWT

- Are both crude tankers and product tankers

Panamax tankers

- Are normally between 650 feet (200 meters) and 820 feet (250 meters) long

- Have a capacity of between 60,000 to 80,000 DWT

- Are both crude tankers and product tankers

- This is the maximum tanker size that can pass through the Panama Canal

Aframax tankers

- Are normally around 790 feet (240 meters) long

- Have a capacity of between 80,000 to 120,000 DWT

- Tankers under 100,000 can be both crude tankers and product tankers

- This is the maximum size of vessel that uses the Average Freight Rate Assessment method for calculating shipping rates

Suezmax tankers

- Are normally around 900 feet (275 meters) long

- Have a capacity of between 120,000 to 200,000 DWT

- Are only crude tankers

- Larger Suezmax tankers are often referred to as supertankers

- This is the maximum tanker size that can pass through the Suez Canal

Very Large Crude Carriers (VLCCs)

- Are normally around 1,100 feet (330 meters) long

- Have a capacity of between 200,000 to 320,000 DWT

- Are only crude tankers

- Often referred to as supertankers

Ultra Large Crude Carriers (ULCCs)

- Are normally around 1,350 feet (415 meters) long

- Have a capacity of between 320,000 to 550,000+ DWT

- Are only crude tankers

- Often referred to as supertankers

- Not many in existence as they are too large for many ports and facilities

How do oil tanker classifications get their names?

If you’ve ever wondered about the slightly ‘unusual’ names given to the classification of oil tankers, here’s a brief explanation.

Read more: Everything You Need to Know About Offshore Vessels

What is a Suezmax tanker?

- Up until 1956 oil tankers were designed and built to enable them to pass through the Suez Canal

- This is why ships that could pass through the Suez are called Suezmax (and why ships that can transit the Panama Canal are called Panamax)

- The Suez Crisis of 1956 made this need to build specifically for the Suez Canal less urgent as shipowners needed to find alternative routes - namely navigating instead around the Cape of Good Hope

- This made shipowners realize that larger tankers were more efficient and economical - the bigger the tanker, the more cheaply it can transport its product

- These huge tankers - larger Suezmax, VLCCs and ULCCs are known as supertankers due to their huge proportions

What is an Aframax tanker?

- The AFRA system (Average Freight Rate Assessment), as a form of size classification for tankers, was created in 1954 by Shell Oil

- The reason behind the system was because the tax authorities requested verification of shipowners’ internal billing records

- This was a result of it being tricky to gauge the cost of oil when it started trading on NYMEX (the New York Mercantile Exchange)

- This is where the name Aframax comes from

What are VLCC and ULCC oil tankers?

- VLCC (Very Large Crude Carriers) and ULCC (Ultra Large Crude Carriers) are the biggest man-made mobile structures in the world

- To put their capacities into perspective, they can carry the equivalent of around 2,000,000 barrels of oil

- All the ULCCs that were built in the 1970s are now scrapped due to their inconvenient size - not many port facilities can host them

- These days the few remaining ULCCs are no longer than 1312 feet (400 meters)

- When they reach their destination, many supertankers offload their cargo of oil to smaller tankers that meet them outside of port.

Oil tanker design and construction

It will come as a shock to no one that oil tankers need to be constructed in a way that limits the potential for environmental devastation in the event of an accident.

Accidents involving oil tankers are, sadly, not a once in a lifetime event and they make global headlines when they occur.

ARE YOU LOOKING FOR JOBS ON OIL TANKERS? VIEW MARTIDE’S OIL TANKER JOBS NOW!

Indeed, the Exxon Valdez oil spill off the coat of Alaska in 1989 is still not too far from the memory of many.

This arguably changed the face of the oil tanker transportation industry with the result being that stricter rules concerning the construction of tankers, and their operation, were enforced worldwide.

Read more: Everything You Need to Know About Pilot Boats

Due to long held concerns over pollution and accidents, such as the 1989 incident, since 1996 the majority of tankers, unless they are very ‘small’, are constructed with a double hull, or a satisfactory alternative.

A double hull gives greater protection against spillage in the event of an accident as the vessel is built with an inner hull inside the outer, with a space between them.

Indeed the MARPOL convention (The International Convention for the Prevention of Pollution from Ships) has stipulated that all existing single-hulled tankers, apart from the very smallest, must be retrofitted with a double hull, or face retirement.

Due to the nature of its cargo, an oil tanker also needs to take the possibility of ignition and an outbreak of fire very seriously. That’s why tankers employ an inert gas system.

And whilst fuel oil is hard to set alight, when air meets its vapor under certain conditions, it can create an explosive atmosphere. Therefore an inert gas system is engaged in order to construct a non-flammable situation inside a tank.

Read more: Everything You Need to Know About LNG & LPG Tankers

And while fires need to be avoided at all costs, in the event of one breaking out, the trusty fireboat will spring into action to attempt to extinguish the flames.

Aside from the double hull design, other features of oil tankers include the fact that the crew accommodation, navigation deck, machinery for propulsion and the cargo pumps (more on those later) are all located at the stern of the vessel.

Along with the fuel and ballast tanks, the rest of the vessel is taken up with the cargo - i.e. crude oil or petroleum products.

A brief history of oil tankers

As the maritime industry and jobs at sea have evolved, so too has the way oil is transported around the world. A lot has changed since oil was first being transported from the former British colony of Upper Burma at the start of the 1850’s.

Using earthenware pots and jugs, the oil was carried to a nearby river where it was poured into the holds of ocean-going vessels that were bound for the United Kingdom. Meanwhile in the United States in the 1860’s, barges and break bulk vessels were used to transport oil from the oil fields of Pennsylvania.

Here, the oil was transported using wooden barrels but this method had more than one drawback: The barrels were expensive, they leaked, they could only be used once under normal circumstances, and they were heavy. Four disadvantages that didn’t make a lot of sense, economically speaking.

The original ‘oil tankers’ also looked drastically different from what we recognize as a tanker today. For a start they were powered by sail and it wasn’t until 1873 that the first oil tanker steamer was built for its Belgian owners. Barges came into some use in 1871 in the USA to help shift the produce of the Pennsylvania oil rush, as did rail tanker cars.

ARE YOU LOOKING FOR JOBS ON OIL TANKERS? VIEW MARTIDE’S OIL TANKER JOBS NOW!

What we now recognize as the ‘modern oil tanker’ started its life in the late 1800’s when development began in 1877 by Swedes Robert and Ludvig Nobel, brothers of the, perhaps better known, Alfred, the creator of the Nobel Prize.

Clearly a family of high achievers, the Nobel brothers researched how to separate the cargo of oil and its fumes away from the engine room so that the potential for fire to break out was reduced.

They designed an oil tanker named Zoroaster which transported its cargo of kerosene in two iron tanks located fore and aft of the midships engine room that were connected by pipes.

The next move was to reduce the potential of a vessel capsizing by designing a new approach to the problems caused by only having one or two holds for the oil.

Obviously any type of liquid cargo is going to ‘slosh around’ which led to instability of the ship. The answer was to add more, smaller holds.

Now most oil tankers usually have between eight and twelve tanks that are then divided into two or three compartments, greatly aiding the vessel’s stability whilst on the move.

How is oil loaded onto a tanker?

Oil needs to be transferred between the tanker and the point on shore and a couple of different methods are used to do this.

Either marine loading arms or cargo hoses are used to pump the oil into the vessel’s tanks as it is docked at a pier, or underwater hoses are used when the tanker moors to an offshore buoy.

In addition, an operation called lightering may be employed, which is when one vessel transfers the oil to another via a hose.

The pumping of the oil will begin at a cautious pace at first to make sure that all of the connections are tight and that the relevant equipment is in the correct position and working properly. When it is certain everything is operating as it should, a steadier pressure is applied.

Gauges are used so that whoever is in charge of the onloading knows how much room they have left in the tank. Clear and direct communication with the people who are pumping the oil into the tanker from their shore-based location must also be maintained.

How is oil discharged from a tanker?

Much like the loading process, when an oil tanker vessel reaches its destination, the discharge process also involves several steps to ensure safe and efficient transfer.

The tanker is securely moored at the port, and specialized hoses or loading arms are connected to the ship's manifold. The onboard pumps then transfer the oil through these connections to the onshore storage facilities.

As before, during this process the crew monitors pressure and flow rates to prevent spills and ensure a smooth operation. Advanced safety systems and protocols are in place to address any potential issues, minimizing environmental impact and ensuring the safe discharge of the oil cargo.

The future of oil tankers

There are legitimate concerns around the safety and ecological aspects of the oil tanker but the fact is, that this is the second most effective and efficient method of transporting oil around the globe, only surpassed by oil pipelines.

ARE YOU LOOKING FOR JOBS ON OIL TANKERS? VIEW MARTIDE’S OIL TANKER JOBS NOW!

Rules, conventions and regulations, such as mandatory double hulls in the vast majority of tankers, are helping to create a safer industry, which is a must as oil tankers aren't going anywhere anytime soon.

Meanwhile, we should raise our hats to the seafarers who work tirelessly aboard them, keeping the global supply chain moving and ensuring the world has the products and commodities we need to survive.

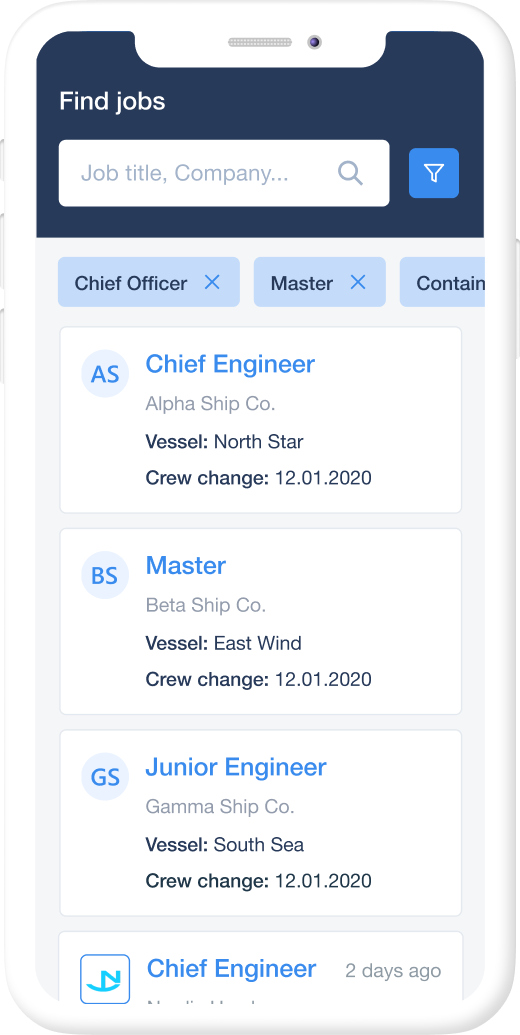

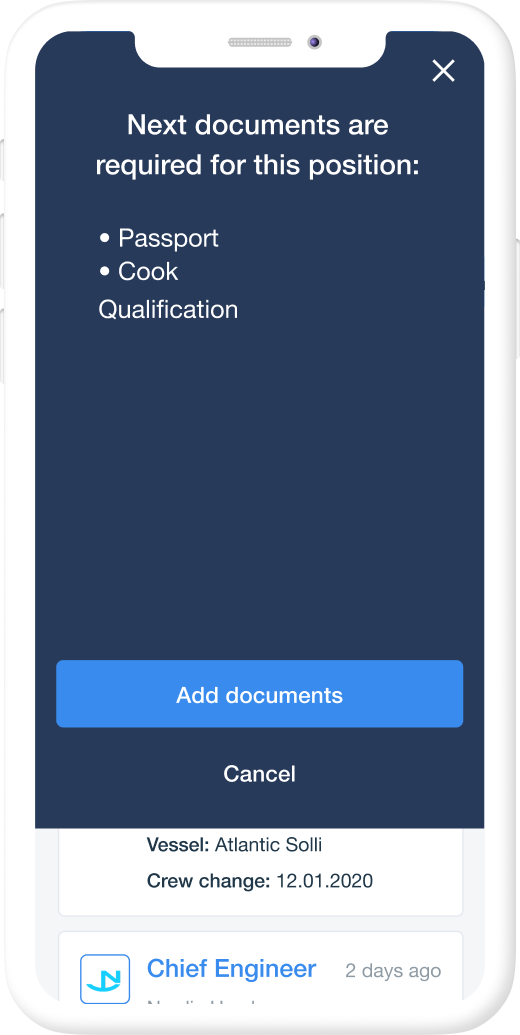

And don’t forget to download our seafarer job app for iOS or Android from the Apple App Store or from Google Play either!

Read the previous article in this series: Everything You Need to Know About Heavy Lift Vessels

Read the next article in this series: Everything You Need to Know About Bulk Carriers

Eve Church

Eve is Martide's content writer, publishing regular posts on everything from our maritime recruitment and crew planning software to life at sea. Eve has been writing professionally for more than two decades, crafting everything from SEO-focused blog posts and website landing pages to magazine articles and corporate whitepapers.

UK